The Foundry Sand Casting Process

Casting bells in bronze offers many advantages. The metal is durable and is highly resistant to corrosion. A wide range of forms and sizes is possible and, most importantly, the bells ring with a strong, pure tone that is unique to bronze.

Casting bells in bronze offers many advantages. The metal is durable and is highly resistant to corrosion. A wide range of forms and sizes is possible and, most importantly, the bells ring with a strong, pure tone that is unique to bronze.

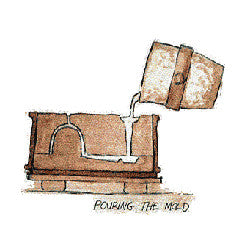

The drawing below illustrates the essentials of sand casting. First a pattern is made from wood or plaster that resembles the finished piece. Sand is packed around the pattern to form a mold impression. This is much like making footprints on wet beach sand. In fact a rough casting could be made by pouring plaster directly into the impression in the sand.

After the mold is packed, the pattern is removed and molten bronze is poured into the finished mold to form the casting.

Step by step...

First a pattern must be made from the original design. The bell is drawn as a finished piece, then a profile of the bell is developed.

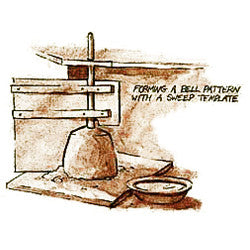

The profile drawing is then transferred to a template which is used as a sweep. Rotating the sweep around setting plaster creates a pattern which can be used as a die to make other pattern copies. As many copies are mounted on a pattern board (called a "match plate") as will fit within the molding frame ("flask").

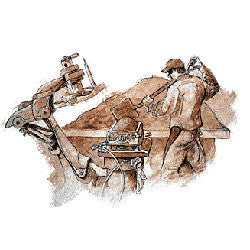

The pattern is placed in the "flask" which rests on the molding machine. A bench will do, but the "jolt-squeeze" molder makes the day go by more easily. This machine has a large air cylinder which will compact the sand against the pattern creating a hard mold. Some patterns do not lend themselves to this squeeze operation and must still be rammed by hand with a bench rammer. Sand is shoveled into the flask, covering the pattern and rammed or squeezed until the mold is full and packed hard.

Molding sand has just enough clay and water mixed in to enable it to bond together with sufficient strength to retain the impression from the pattern even after the pattern is removed. Here the mold has been opened. The molder will remove the pattern, cut the "spru hole" through the top half ("cope side"), blow away any loose sand from the mold faces, and then close the mold and clamp it or weight it for pouring.

The "spru hole" is like a funnel to direct the molten bronze into the mold cavity. The bronze is poured down the spru hole until the mold fills to the top. Bronze melts at about 1800°F, but we must heat it all the way to 2150°F to be sure it stays molten long enough to completely fill the mold.

Painting and illustrations on this page by Josh Fisher

“Our Bell Process”- This video takes you through our bell making process from casting the bronze to machining the finished castings and finally assembling the bells.

"The Pour" This is a video of pouring bronze into sand molds at the US Bells foundry. The crucible containing 90 pounds of molten bronze at a temperature of 2150° F. is removed from the furnace and the floating slag skimmed from the surface. The metal must be poured smoothly but quickly into each mold to assure the castings do not ‘freeze’ before they are full. After removing the weights and ‘jackets’, the molds are broken open to reveal the new castings.